TurboFil offers solutions for small parts, medical devices, and o-ring assembly. These solutions can be integrated into existing systems allowing for accurate and reliable results. Our engineers are experts in factory automation and can develop a turnkey system to fit your companies needs.

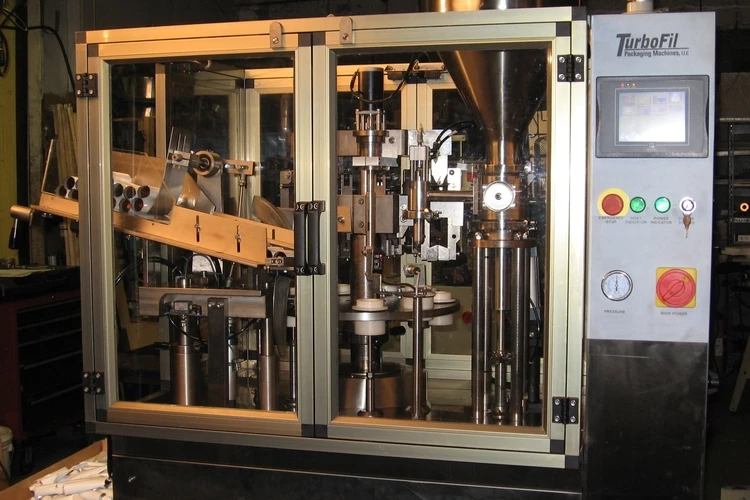

Function: Fully automatic tube filling and sealing system for aluminum, plastic, and laminate tubes with integrated orientation, filling, sealing, and coding.

Container : Supports metal, plastic, or laminate tubes

Output : Up to 40 tubes/min (plastic/laminate), up to 60 tubes/min (metal tubes), depending on size and tube material.

Material Handling: Low to high viscosity

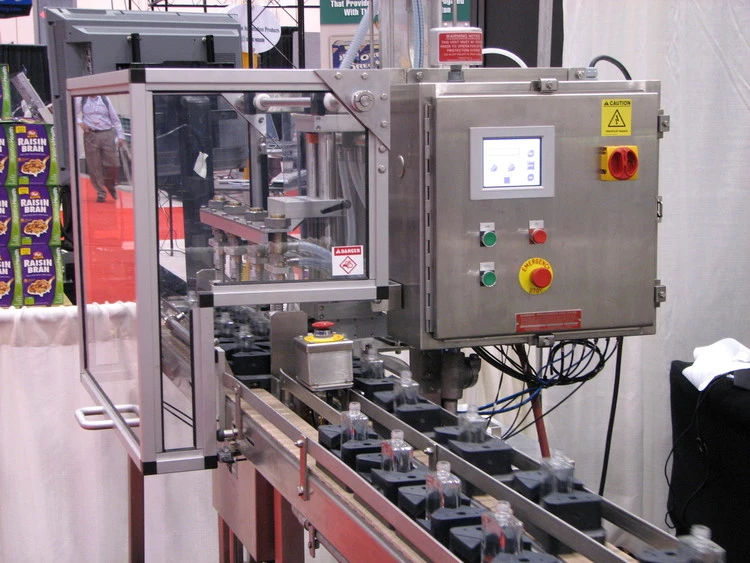

Function: Inline filling and closing system using adjustable pucks for rapid changeover between various bottle shapes and sizes—no change parts required.

Container : Handles a wide range of glass or plastic bottles, vials, or jars

Output : Up to 60 units per minute

Material : suitable for perfumes, lotions, creams, and more.

Function: Semi-automatic syringe filling and capping system with tip-based filling using an indexing dial and dual-syringe processing.

Container Supports a range of single-chamber syringe sizes

Output : Up to 80 parts per minute

Material : Low to high viscosity

Function: Fully automatic filling system for single and dual-barrel syringes with servo-controlled, bottom-up filling for precise control and clean operation.

Container : Supports single or dual-barrel syringes

Output : Operates at 15–35 syringes per minute,

Material : High viscosity

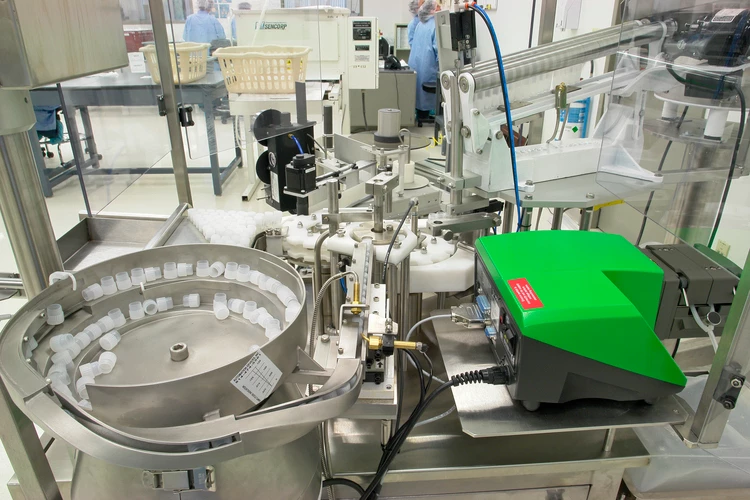

Function: Semi-automatic benchtop vial capping system with hands-free torque control for efficient small-batch processing.

Container : Designed for vials held in Delrin “boats” (10–20 vials per boat depending on size);

Output : Up to 30 vials per minute;

Material : Pharmaceutical, cosmetic, chemical

Function: Universal rotary indexing platform for pacing operators and semi-automated filling and assembly tasks.

Container : Supports various container types and sizes, including irregularly shaped perfume bottles and vials up to 4 oz.

Output : Operator-paced system with optional automation; ideal for short to medium runs and multi-function workflows.

Material :Material has no impact

- Function: Bench-top volumetric piston filler designed for precise filling

-

Container : Ideal for small cosmetic containers; fill range from 7–30ml.

-

Output : Up to 20 cycles per minute

-

Material: Handles a wide range of viscosities

Function: Compact tabletop monoblock system for automatic filling and capping or crimping of small bottles and vials—no conveyor required.

Container : Supports glass or plastic bottles and vials

Output: 15–40 units per minute

Material : Low to high viscosity liquids

Function: Fully automatic monoblock system for filling and assembling mascara or lip gloss containers, including bottle loading, filling, wiper insertion, and cap/applicator placement.

Container: Handles round, square, triangular, or irregular-shaped bottles

Output : Up to 50 bottles per minute, with high-precision piston pump and bottom-up filling for consistent, drip-free performance.

Material : Mascara

-

Function: Automatic pneumatic tamper for seating valves, decorative collars, or overcaps onto perfume bottles.

-

Container: Designed for perfume bottles; compatible with various collar and cap styles.

-

Output : Speed-matched to IC-60 crimper; suitable for continuous or batch operations.

-

Material : Available with automatic loading for collars or caps to streamline assembly

-

Skip to content

Skip to content