Understanding the Different Types of Capping Machines and Their Industry Applications

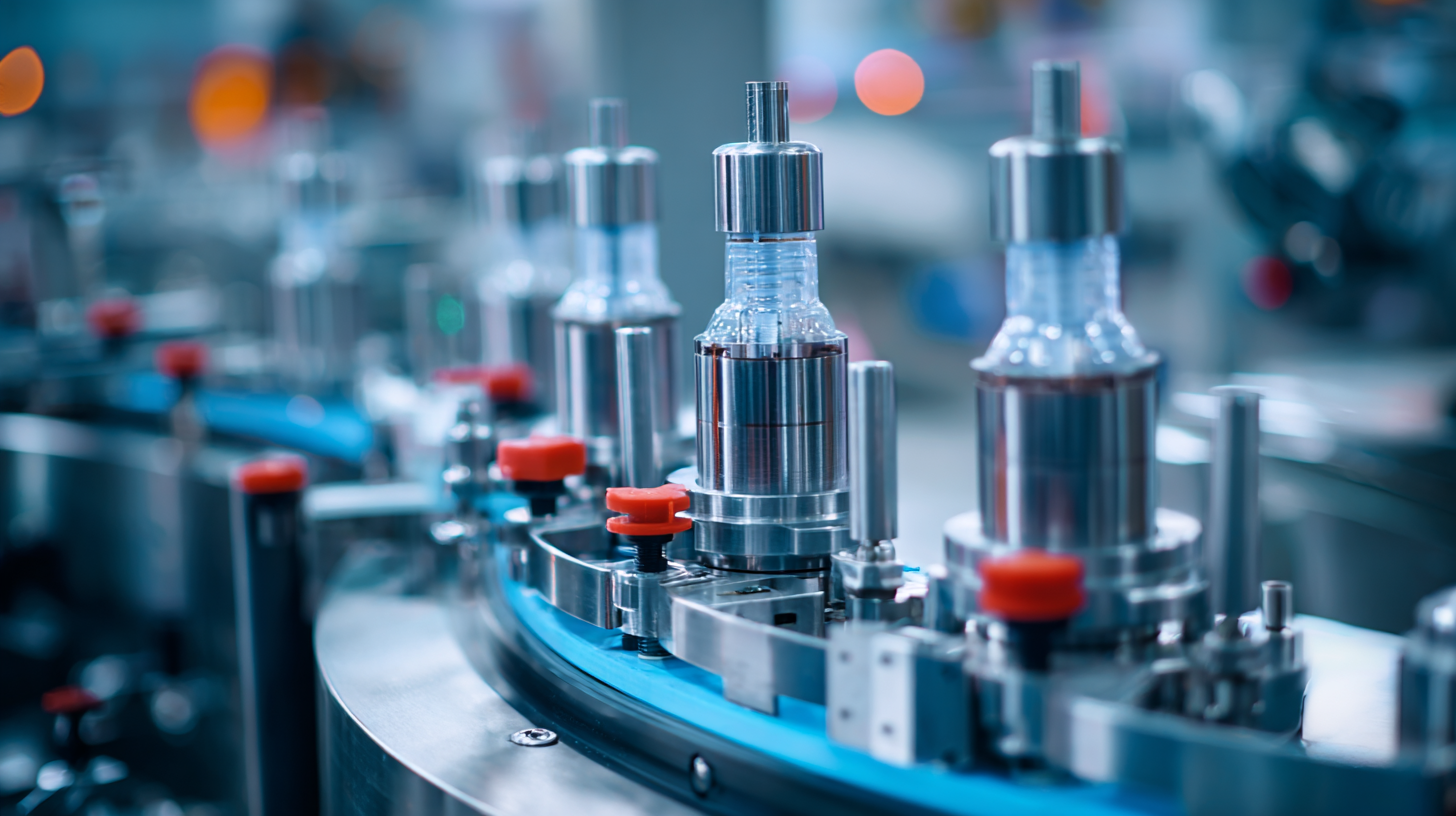

The demand for capping machines has surged as industries strive for efficiency and precision in their packaging processes. According to a recent report by MarketsandMarkets, the global capping machine market is projected to reach $4.8 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.8% during the forecast period. This growth is largely driven by the increasing need for stringent packaging standards in sectors like food and beverage, pharmaceuticals, and cosmetics. As producers seek to enhance product integrity and safety, understanding the various types of capping machines and their specific applications becomes crucial. From semiautomatic models suited for smaller production runs to highly automated systems for large-scale operations, the right choice of capping machine can significantly impact productivity and operational costs across different industries.

Types of Capping Machines: A Comprehensive Overview

Capping machines play a crucial role in various industries by ensuring that containers are securely sealed. Understanding the different types of capping machines is essential for manufacturers looking to optimize their production lines. There are primarily three categories of capping machines:

spindle cappers, chuck cappers, and inline cappers.

Spindle cappers utilize rotating spindles to tighten caps, making them ideal for high-speed applications on production lines with lightweight caps. Chuck cappers, on the other hand, employ a gripping mechanism to apply torque, providing a more secure seal, especially for heavier caps that require precise application.

Capping machines play a crucial role in various industries by ensuring that containers are securely sealed. Understanding the different types of capping machines is essential for manufacturers looking to optimize their production lines. There are primarily three categories of capping machines:

spindle cappers, chuck cappers, and inline cappers.

Spindle cappers utilize rotating spindles to tighten caps, making them ideal for high-speed applications on production lines with lightweight caps. Chuck cappers, on the other hand, employ a gripping mechanism to apply torque, providing a more secure seal, especially for heavier caps that require precise application.

Inline cappers are designed for versatility, accommodating a range of cap types and sizes. They are integrated into an assembly line, allowing for continuous operation and reducing the downtime associated with changeovers. Each type of capping machine is suited for specific applications — from beverage bottling and cosmetic packaging to pharmaceutical products. By choosing the appropriate capping machine, businesses can enhance efficiency, maintain product integrity, and meet industry regulations while adapting to market demands.

Key Features of Different Capping Machine Designs

Capping machines are vital in the packaging industry, with various designs tailored for specific applications. Key features such as torque control, speed, and automation levels significantly influence their suitability. For example, automatic capping machines, which are increasingly popular, can operate at speeds exceeding 200 bottles per minute, according to a recent report by the Packaging Machinery Manufacturers Institute (PMMI). This high efficiency meets the growing demands of industries like beverages, pharmaceuticals, and cosmetics, where production speed is crucial.

Another important feature is the type of closure being applied. Some capping machines handle screw caps, while others are designed for snap-on or press-on caps. Data from the Freedonia Group reveals that the global demand for capping equipment is projected to grow by 4% annually, with a notable increase in the beverage sector driving innovation. Additionally, advanced models incorporate smart technologies, allowing for real-time monitoring and adjustments, ensuring quality control and reducing waste. This adaptability underscores the necessity of choosing the right type of capping machine based on the specific product requirements and industry standards.

Industry Applications: Choosing the Right Capping Machine

When selecting the right capping machine for a specific industry application, it’s essential to consider various factors such as speed, bottle types, and closure types. According to a report from Grand View Research, the global capping machine market is expected to reach $4.5 billion by 2028, driven by the increasing demand for packaged goods across various sectors, including food, pharmaceuticals, and cosmetics. Different industries have distinct requirements: for instance, the food industry may prioritize speed and hygiene, necessitating advanced capping machines that can handle high throughput while maintaining safety standards.

**Tip:** Always assess the compatibility of the capping machine with your production line setup. Machines that allow easy integration can significantly reduce downtime and enhance overall efficiency. Additionally, consider the material and design of the closures; some machines are specifically engineered for plastic closures, while others excel with metal caps.

The pharmaceutical industry emphasizes precision in capping, as improper sealing can lead to contamination and product spoilage. Data from Technavio suggests that the increasing adoption of automated capping solutions in pharmaceuticals is driven by stringent regulatory requirements and the need for consistent quality. To ensure you select the right machine, conduct thorough market research and consult industry experts to align your needs with the latest advancements in capping technology.

**Tip:** Before finalizing your choice, request product demos or trials to evaluate machine performance and adjust settings according to your specific production needs.

Understanding the Different Types of Capping Machines and Their Industry Applications

Comparative Analysis of Capping Machines by Cap Type

When it comes to encapsulating products, understanding the various types of capping machines based on cap type is crucial for manufacturers.

There are primarily three categories: screw capper machines, snap capper machines, and crown capper machines. Each machine is designed with specific applications in mind, tailoring their functionalities to fit different types of closure mechanisms and products, from beverages to pharmaceuticals.

Screw cappers are ideal for threaded caps, providing efficient sealing for bottles in high-speed environments. Conversely, snap cappers are engineered for caps that click into place without threads, making them perfect for soft drink bottles. Crown cappers, often used in the brewing industry, are designed for metal crown caps that fit tightly on glass containers.

When selecting a capping machine, consider the type of cap you will be using and the production rate required. It's essential to ensure that the chosen machine accommodates the cap size and type while maintaining consistent pressure to prevent leakage. Additionally, always prioritize reliability; investing in a machine that offers easy maintenance will save time and costs in the long run.

Future Trends in Capping Machine Technology and Innovation

The future of capping machine technology is poised for significant transformation, driven by innovations that promise to enhance efficiency and precision in various industries. One major trend is the integration of automation and robotics, enabling capping machines to operate at a faster rate while minimizing human intervention. This shift not only increases production speed but also reduces the potential for errors, thereby enhancing overall product quality. Additionally, advanced sensors and machine learning algorithms are being employed to monitor and adapt the capping process in real-time, ensuring a consistent and reliable sealing process that meets stringent quality standards.

Moreover, sustainability is becoming a central focus in the development of capping machines. Manufacturers are increasingly exploring eco-friendly materials and energy-efficient designs to reduce their environmental footprint. Innovations such as lightweight components and reduced power consumption are being prioritized, aligning with global efforts toward greener production methods. As industries continue to demand more adaptive and sustainable solutions, the capping machine sector is expected to evolve, embracing technologies that not only fulfill operational needs but also contribute to a more sustainable future.

Related Posts

-

7 Essential Tips for Choosing the Perfect Bottle Labeler

-

Maximizing Efficiency with Automatic Label Applicator Benefits for Global Buyers

-

What is a Capping Machine for Bottles and How Can It Benefit Your Production Line?

-

Ultimate Guide to Choosing the Right Label Applicator Machine for Your Business

-

Exploring Innovative Examples of Capping Machine Technologies in Today's Bottling Industry

-

The Future of Oil Filling Machines in the Evolving Packaging Industry

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content