Revolutionizing Packaging: The Unseen Benefits of Automatic Bottle Capping Machines in Modern Production

In the rapidly evolving landscape of manufacturing, the introduction of advanced technologies has significantly transformed traditional production processes. Among these innovations, the bottle capping machine stands out as a pivotal element in the packaging sector. According to a recent report by Smithers Pira, the global packaging industry is projected to reach $1 trillion by 2024, driven by increasing demand for convenience and efficiency. Automatic bottle capping machines streamline the capping operation, enhancing speed and precision while reducing labor costs. Furthermore, the adoption of these machines can minimize product contamination and enhance shelf life, thereby improving consumer safety and satisfaction. As businesses strive to optimize production lines, the unseen benefits of automatic bottle capping machines are becoming increasingly indispensable in modern production environments.

The Importance of Automation in Modern Packaging Industries

The modern packaging industry is undergoing a significant transformation driven by automation. Automatic bottle capping machines exemplify this shift, offering enhanced precision and efficiency in production lines. By minimizing human error and increasing speed, these machines ensure that products are sealed securely and consistently, critical factors in maintaining product quality and safety. This technological advancement not only boosts productivity but also allows companies to allocate resources more efficiently, reducing operating costs in the long run.

Tip: When investing in automatic capping machines, consider models that offer flexibility for different bottle sizes and cap types. This adaptability can significantly benefit companies that handle various products, enabling them to streamline their processes without extensive modifications.

Moreover, automation in packaging not only improves operational efficiency but also enhances the overall consumer experience. Automated systems can be integrated with quality control technologies, ensuring that only products meeting stringent standards reach the market. This reliability fosters consumer trust and brand loyalty, positioning companies for long-term success in a competitive landscape.

Tip: Regular maintenance and updates to automated systems can enhance their longevity and performance. Implementing a scheduled maintenance plan helps prevent downtime and ensures that machinery operates at optimal efficiency.

Key Features of Automatic Bottle Capping Machines

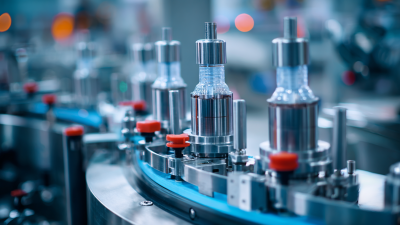

Automatic bottle capping machines play a crucial role in modern production lines, providing efficiency and consistency that manual processes simply cannot match. One key feature of these machines is their ability to handle a wide range of bottle sizes and cap types, accommodating the diverse needs of various industries. According to a report by MarketsandMarkets, the global packaging machinery market is projected to reach USD 50 billion by 2025, highlighting the increasing adoption of automation in production environments.

Automatic bottle capping machines play a crucial role in modern production lines, providing efficiency and consistency that manual processes simply cannot match. One key feature of these machines is their ability to handle a wide range of bottle sizes and cap types, accommodating the diverse needs of various industries. According to a report by MarketsandMarkets, the global packaging machinery market is projected to reach USD 50 billion by 2025, highlighting the increasing adoption of automation in production environments.

Another significant feature is the speed and precision of automatic capping systems. These machines can achieve speeds of up to 600 bottles per minute, significantly reducing bottleneck occurrences in production. This high throughput is vital for meeting market demands, especially in fast-paced industries such as food, beverage, and pharmaceuticals. A recent study found that incorporating automatic capping machines can lead to a 30% increase in overall efficiency, allowing companies to maximize their output without compromising quality.

Tip: When selecting an automatic bottle capping machine, consider features like ease of operation and maintenance requirements. Machines with quick-change capabilities can save valuable time during product changeovers. Additionally, investing in machines that incorporate smart technology can provide data analytics to help monitor performance and predict maintenance needs, ultimately enhancing operational efficiency.

Cost Efficiency: How Automation Reduces Operational Expenses

The increasing adoption of automatic bottle capping machines in modern production lines has brought significant cost efficiencies that are often overlooked. Traditional capping methods are labor-intensive, requiring skilled workers for manual placement and tightening of caps, which can lead to increased labor costs and inefficient use of time. By integrating automated capping solutions, companies can streamline these processes, reducing the requirement for manual oversight and minimizing labor expenses. The result is a more cost-effective production line that maintains high output levels.

Moreover, automatic bottle capping machines enhance operational efficiency beyond mere labor savings. These machines ensure consistent application of pressure, reducing the risk of product leaks and spoilage, which can lead to costly waste and returns. By maintaining strict quality control through automated processes, businesses can maximize their yield while taking advantage of reduced raw material loss. As manufacturers continue to seek competitive advantages in an evolving market, the financial benefits provided by automation in capping technologies become increasingly crucial.

Enhancing Production Speed and Consistency with Automatic Capper

In today's fast-paced manufacturing environment, automatic bottle capping machines are essential for enhancing production speed and consistency. These machines not only streamline the capping process but also minimize human error, ensuring that every bottle is sealed perfectly every time. With the ability to operate at high speeds, businesses can significantly increase their output while maintaining quality, ultimately leading to higher customer satisfaction and reduced operational costs.

**Tips for Optimizing Your Automatic Capping Process:**

1. Regular Maintenance: Ensure that the machine is regularly maintained to avoid downtime and prolong its lifespan. Simple checks can prevent major issues down the line.

2. Train Your Staff: Provide adequate training for your staff on how to operate and troubleshoot the capping machines, maximizing efficiency and minimizing potential errors.

3. Monitor Production: Use technology to monitor the production line. Metrics such as capping speed and percentage of misaligned caps can highlight areas for improvement.

As industries move towards automation, adopting these high-performance capping solutions allows manufacturers to stay competitive while meeting the increasing demands for faster production without compromising on quality. Embracing these innovations not only boosts efficiency but also positions a company as a leader in the market, prepared for the future of production.

Revolutionizing Packaging: The Unseen Benefits of Automatic Bottle Capping Machines in Modern Production

| Feature | Manual Capping | Automatic Capping |

|---|---|---|

| Production Speed (bottles/hour) | 200 | 1200 |

| Consistency (cap application error rate) | 5% | <1% |

| Labor Costs (%) | 30% | 10% |

| Maintenance Frequency (per year) | Monthly | Quarterly |

| Setup Time (minutes) | 60 | 15 |

Quality Control: The Role of Technology in Packaging Reliability

In the fast-paced world of modern production, automatic bottle capping machines have become indispensable, particularly in ensuring quality control. According to a recent industry report by Grand View Research, the global packaging machinery market is projected to reach $63.93 billion by 2028, driven largely by innovations in automation technology. These machines enhance reliability by providing consistent torque application, which minimizes the risk of leaks and contamination. Additionally, integrating vision systems with capping machines enables real-time monitoring, ensuring that every cap meets stringent quality standards.

**Tips:** Invest in systems that provide comprehensive data analytics. This will not only allow for immediate adjustments during the production process but also facilitate long-term enhancements in quality assurance. Furthermore, regular maintenance of equipment is crucial; a report from the Packaging Machinery Manufacturers Institute highlights that proactive maintenance can reduce breakdowns by 25%, significantly increasing production efficiency.

As the market evolves, leveraging technology for packaging reliability is paramount. Automated systems significantly reduce human error while improving operational speed. A McKinsey report states that factories utilizing automated solutions can achieve up to 30% higher productivity. Implementing such technologies not only meets consumer demand for high-quality products but also solidifies a company's reputation in competitive markets.

Related Posts

-

How Bottle Labeling Machines Revolutionize Efficiency in Packaging Industries

-

How to Choose the Perfect Lip Gloss Filling Machine for Your Production Needs

-

Understanding the Different Types of Capping Machines and Their Industry Applications

-

How to Choose the Right Bottle Labeler for Your Business Needs

-

7 Essential Tips for Choosing the Perfect Bottle Labeler

-

Exploring Trends in Bottle Filling Machines at China’s 138th Canton Fair 2025

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content