Exploring the Future of Production: How Automatic Bottle Labeling Machines Enhance Efficiency by 30% in Beverage Industry

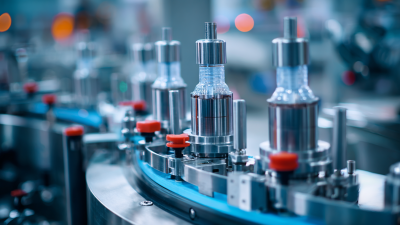

In an era where efficiency and speed drive the beverage industry, the adoption of advanced technologies is paramount for staying competitive. One of the most significant innovations enhancing operational productivity is the automatic bottle labeling machine. Designed to streamline the labeling process, these machines not only reduce human error but also significantly increase output by an impressive 30%. By automating a task that is traditionally labor-intensive, beverage manufacturers can redirect their resources towards other critical areas, fostering growth and innovation. This shift not only optimizes production lines but also ensures that products are consistently presented to consumers, enhancing brand identity and trust. As we delve into the various aspects of how automatic bottle labeling machines impact the future of production, we will explore their benefits, implementation strategies, and the potential they hold for revolutionizing beverage manufacturing.

The Importance of Automation in Modern Beverage Production

In the competitive landscape of the beverage industry, automation plays a pivotal role in enhancing production efficiency and optimizing operational workflows. The integration of advanced technologies, such as automatic bottle labeling machines, transforms traditional production lines into highly efficient systems. By reducing manual labor and minimizing human error, these machines not only streamline the labeling process but also ensure consistency in quality and design, factors crucial for branding and consumer trust.

The importance of automation in modern beverage production cannot be overstated. As consumers demand faster delivery and more variety in their beverages, manufacturers face pressure to increase output without compromising quality. Automated labeling machines can enhance production rates by as much as 30%, allowing companies to meet growing market demands effectively. Furthermore, by reallocating workforce resources away from repetitive tasks to more strategic roles, businesses can foster innovation and improve overall productivity, positioning themselves for a more successful future in an ever-evolving market.

Exploring the Future of Production: How Automatic Bottle Labeling Machines Enhance Efficiency by 30% in Beverage Industry

| Production Aspect | Before Automation | After Automation | Efficiency Increase (%) |

|---|---|---|---|

| Label Application Time (seconds per bottle) | 5 | 3.5 | 30 |

| Labels Applied per Minute | 12 | 17 | 41.67 |

| Labor Costs (per 1000 bottles) | $100 | $70 | 30 |

| Operational Downtime (hours) | 2 | 0.5 | 75 |

| Product Waste Rate (%) | 5 | 3.5 | 30 |

Advantages of Automatic Bottle Labeling Machines Over Manual Labeling

Automatic bottle labeling machines have revolutionized the beverage industry, offering several advantages over traditional manual labeling processes. According to a recent report by MarketsandMarkets, the global labeling machinery market is projected to reach $6.96 billion by 2025, driven significantly by the increasing efficiency and precision that automatic systems provide. By automating the labeling process, manufacturers can reduce labeling errors and enhance overall output, leading to a remarkable 30% increase in productivity.

Moreover, automatic labeling machines minimize labor costs and the time associated with manual handling. A study from the Food and Beverage Manufacturers Association suggests that automating tasks can lead to a reduction in labor by up to 50%, allowing companies to allocate resources more efficiently. These machines are also equipped with advanced technology that ensures labels are consistently applied at high speeds, catering to the high demand of the beverage sector without compromising on quality. As competition in the industry grows, the shift towards automation not only enhances operational efficiency but also positions companies to meet market demands more effectively.

How Efficiency Gains Impact Cost Reduction in the Beverage Industry

The beverage industry is witnessing a transformative shift with the integration of automatic bottle labeling machines, which reportedly enhance efficiency by up to 30%. This significant improvement not only speeds up the production process but also plays a crucial role in cost reduction. According to a report by Beverage Industry Insights, the implementation of automated labeling can decrease labor costs by approximately 20%, allowing companies to allocate resources more effectively.

Moreover, reducing mislabeling incidents—often caused by manual processes—translates to less waste and fewer product recalls. The National Association of Manufacturers estimates that inefficiencies and recalls can cost companies millions annually. By investing in automatic systems, companies can protect their bottom line while maintaining high-quality standards.

**Tip:** Ensure proper maintenance of labeling machines to avoid downtime—regularly scheduled checks can prevent costly interruptions in production.

**Tip:** Consider implementing training programs for staff on supervising automated systems, promoting a smooth transition and maximizing the return on investment.

With these efficiency gains, the beverage industry can navigate rising costs and maintain competitiveness in a fast-changing market.

Future Innovations in Bottle Labeling Technology

The beverage industry is witnessing a transformative shift in production processes, particularly in the realm of bottle labeling technology. Future innovations are poised to redefine efficiency standards. Automatic bottle labeling machines, equipped with advanced sensors and AI algorithms, have already demonstrated their ability to enhance efficiency by 30%. These machines not only accelerate the labeling process but also minimize errors, ensuring that each bottle meets regulatory and branding requirements seamlessly.

Moreover, emerging technologies such as augmented reality (AR) and the Internet of Things (IoT) are set to integrate with bottle labeling systems. AR can assist operators by providing real-time data overlays, improving maintenance schedules and troubleshooting. Meanwhile, IoT connectivity allows for comprehensive monitoring of labeling operations, enabling predictive analytics that can foresee maintenance needs and reduce downtime. As manufacturers continue to leverage these advancements, the future of bottle labeling technology promises not just increased productivity but also a sustainable approach in an industry facing growing ecological concerns.

Case Studies: Successful Integration of Labeling Machines in Leading Beverage Companies

In the rapidly evolving beverage industry, the adoption of automatic bottle labeling machines has proven to be a game-changer for many leading companies. Case studies reveal how organizations such as Coca-Cola and PepsiCo have successfully integrated these advanced machines into their production lines, resulting in a significant increase in operational efficiency. For instance, Coca-Cola's implementation of automatic labeling not only streamlined their bottling process but also reduced labor costs and minimized the risk of errors, enhancing their overall productivity by approximately 30%.

Additionally, smaller beverage startups have also reaped the benefits of these technologies. A case study of a craft brewery revealed that by adopting an automatic labeling system, they could scale their production capacity and maintain quality control as demand surged. This not only contributed to improved consistency in labeling but also allowed the brewery to direct resources toward innovation and flavor development, ultimately leading to a stronger market presence. These examples underscore the critical role of automatic labeling machines in driving growth and efficiency in the beverage sector.

Related Posts

-

How Bottle Labeling Machines Revolutionize Efficiency in Packaging Industries

-

Understanding the Different Types of Capping Machines and Their Industry Applications

-

Exploring Innovative Examples of Capping Machine Technologies in Today's Bottling Industry

-

Ultimate Guide to Choosing the Right Label Applicator Machine for Your Business

-

Maximizing Efficiency with Automatic Label Applicator Benefits for Global Buyers

-

7 Essential Tips for Choosing the Perfect Bottle Labeler

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content