How to Choose the Right Automatic Liquid Filling Machine for Your Business Needs

In today's fast-paced manufacturing landscape, selecting the right automatic liquid filling machine is crucial for businesses aiming to improve efficiency and maintain product quality. According to recent market research reports, the global liquid filling machine market is expected to reach a value of $8 billion by 2027, growing at a CAGR of 5.2% from 2020 to 2027. This growth highlights the increasing demand for automation in production lines, where precise filling is essential to meet consumer expectations and regulatory requirements.

Whether you are in the beverage, pharmaceutical, or cosmetic industry, choosing the appropriate automatic liquid filling machine can significantly impact your operational productivity and profitability. Understanding the various options available—such as volumetric, peristaltic, or piston fillers—will empower you to make an informed decision that aligns with your business needs and enhances your competitive edge in the market.

Identifying Your Product Type and Requirements for Filling

When selecting an automatic liquid filling machine, the first step is to accurately identify the type of product you are handling and the specific requirements for filling. From thin liquids like water to more viscous substances such as creams or oils, the nature of your product significantly influences the type of filling machine you should invest in. According to a report by Allied Market Research, the global liquid filling machine market is projected to reach $3.8 billion by 2027, reflecting the increasing demand for tailored solutions in various industries including food and beverage, pharmaceuticals, and cosmetics.

Understanding the required filling volume and speed is also crucial. For example, a manufacturing facility looking to fill large containers at high volumes may require a different machine compared to a company focusing on smaller, more precise fills. The National Association of Manufacturers indicates that production speed can reach up to 100 BPM (bottles per minute) with advanced automatic systems. Choosing a machine that meets your output requirements and product characteristics will streamline your operations and ensure consistency in your production line.

How to Choose the Right Automatic Liquid Filling Machine for Your Business Needs

| Product Type | Filling Volume | Filling Speed | Machine Type | Special Features |

|---|---|---|---|---|

| Liquid Soap | 100 - 500 ml | 30 - 50 bottles/min | Piston Filler | Automatic CIP, Adjustable Flow Rate |

| Juice | 250 - 1000 ml | 40 - 60 bottles/min | Gravity Filler | Vacuum System, No Drip Spout |

| Cooking Oil | 500 - 2000 ml | 25 - 40 bottles/min | Overflow Filler | Anti-Leak, Touchscreen Control |

| Pharmaceutical | 10 - 500 ml | 20 - 30 bottles/min | Peristaltic Pump Filler | Sterilizable, Easy to Clean |

| Cosmetics | 30 - 300 ml | 35 - 55 bottles/min | Servo Filler | High Precision, Customizable Settings |

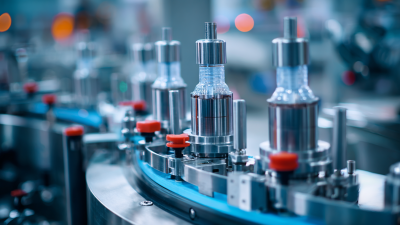

Understanding Different Types of Automatic Liquid Filling Machines

When selecting an automatic liquid filling machine for your business, it’s essential to understand the various types available to align your choice with your specific needs. One popular option is the volumetric filling machine, which dispenses a precise volume of liquid into each container. This type is ideal for products with a consistent viscosity, such as water or sauces, ensuring accuracy and minimized waste.

Another category is the gravity filling machine, which relies on the force of gravity to fill containers from above. These machines are often suited for thinner liquids and are known for their simplicity and ease of use. Conversely, piston filling machines are designed for thicker products, such as creams or gels, utilizing a piston mechanism to deliver a specific volume. Recognizing the unique features and applications of each type will help you make an informed decision that enhances your production efficiency and meets your quality standards.

Evaluating Production Volume and Speed Needs for Your Business

When selecting an automatic liquid filling machine, understanding your production volume and speed requirements is crucial. The first step is to assess your current and anticipated production levels. If your business is in a growth phase or plans to scale, it’s essential to invest in a machine that can handle increased capacity without compromising efficiency. Machines are available in various models, from low-speed options suitable for smaller operations to high-speed machines capable of filling hundreds of bottles per minute. Consider your average daily production goal and choose a machine that meets or exceeds that figure to avoid bottlenecks.

Speed is another vital factor to evaluate. Depending on your industry’s demands, the filling speed can directly impact overall productivity. It’s important to balance speed with accuracy; faster machines can sometimes sacrifice precision, leading to waste and customer dissatisfaction. Therefore, identify a filling machine that optimally aligns with your speed requirements while maintaining proper filling accuracy. Furthermore, ensure that the machine is versatile enough to handle different liquid types and volumes, allowing your business to adapt quickly to changing market demands. This thoughtful evaluation will ensure that you choose the right filling machine tailored to your operational needs.

Considering Budget and ROI When Selecting a Filling Machine

When selecting the right automatic liquid filling machine for your business, understanding the

budget and potential

return on investment (ROI) is crucial. According to a report by MarketsandMarkets, the global

liquid filling machine market is projected to grow from $4.8 billion in 2021 to $6.2 billion by 2026,

underscoring the increasing reliance on automation for efficiency and cost savings. Businesses must weigh not only the upfront costs

of the machinery but also the long-term value it brings through enhanced productivity and precision in filling processes.

Investing in a filling machine that can handle various liquid viscosities can further elevate ROI. A recent industry study indicates

that companies using advanced filling technology can reduce filling time by up to 50%, resulting

in significant labor cost savings over time. Moreover, automatic liquid filling machines minimize waste and ensure better accuracy,

which can lead to improved product quality and customer satisfaction—key factors in maintaining a competitive edge. By analyzing these

financial metrics and utilizing reliable data, businesses can make informed decisions that align with their operational needs and

financial objectives.

Assessing Space and Configuration for Optimal Machine Placement

When selecting the right automatic liquid filling machine for your business, the assessment of space and configuration is crucial for optimal machine placement. Begin by evaluating the available floor space in your facility, considering both the dimensions of the machinery and the workflow it necessitates. A well-planned layout should facilitate seamless operations, allowing for easy access for operators and maintenance, while also promoting efficient movement of products through the filling process.

Additionally, consider the height and width of the machine in relation to the surrounding infrastructure, such as overhead beams or shelving units. It’s important to leave sufficient clearance for loading and unloading products, as well as for any additional components like conveyors or capping machines. Configuring the space to accommodate proper ventilation, lighting, and even utility access points can further enhance the efficiency and safety of your liquid filling operations, ultimately leading to better productivity and reduced downtime.

Related Posts

-

Maximizing Efficiency with Automatic Label Applicator Benefits for Global Buyers

-

What is a Capping Machine for Bottles and How Can It Benefit Your Production Line?

-

Ultimate Guide to Choosing the Right Label Applicator Machine for Your Business

-

Understanding the Different Types of Capping Machines and Their Industry Applications

-

5 Amazing Tips for Choosing the Right Lotion Filling Machine for Your Business

-

7 Essential Tips for Choosing the Perfect Bottle Labeler

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content