How to Choose the Perfect Lip Gloss Filling Machine for Your Production Needs

Choosing the right lip gloss filling machine is crucial for any cosmetics manufacturer looking to optimize their production process and meet market demands. With the increasing popularity of lip gloss products, selecting a machine that aligns with your specific production needs can significantly impact efficiency, product quality, and overall profitability.

This guide will explore the essential factors to consider when choosing a lip gloss filling machine, including production capacity, filling accuracy, ease of operation, and maintenance requirements. Whether you are a startup or an established brand looking to upgrade your equipment, understanding these key aspects will help you make an informed decision, ensuring that your production process runs smoothly and meets the expectations of your customers.

Understanding Your Production Requirements for Lip Gloss

Choosing the right lip gloss filling machine necessitates a comprehensive understanding of your specific production requirements. According to a recent industry report from Allied Market Research, the global lip gloss market is projected to reach $3.6 billion by 2027, growing at a CAGR of 5.4% from 2020 to 2027. This growth indicates an increasing demand for efficient and reliable filling solutions that can keep up with production volume and consistency.

When assessing your production needs, consider factors such as batch size, filling speed, and the viscosity of the lip gloss formulation. Machines that can efficiently handle different viscosities and maintain precise volume control are vital, as variations in formulation can affect both the filling process and product quality. For example, a report by Grand View Research highlights that manufacturers increasingly demand equipment that can perform at speeds of over 100 bottles per minute, especially for high-throughput lines. Understanding these nuances will not only streamline your production but also enhance the overall quality of your lip gloss product.

How to Choose the Perfect Lip Gloss Filling Machine for Your Production Needs - Understanding Your Production Requirements for Lip Gloss

| Feature | Description | Importance | Recommended Specifications |

|---|---|---|---|

| Production Speed | The rate at which lip gloss can be filled and sealed. | High | 100-200 units per minute |

| Filling Accuracy | Precision in filling the containers to avoid overflow or under-filling. | High | ±0.5 ml |

| Machine Size | Physical dimensions of the machine depending on the production area. | Medium | Compact size, suitable for small to medium production lines |

| Ease of Use | User-friendly interface and simple operation. | High | Touchscreen controls |

| Versatility | Ability to handle different lip gloss formulations. | Medium | Compatible with both thick and thin consistencies |

| Maintenance | Frequency and complexity of required maintenance. | Medium | Easy access to internal components for cleaning |

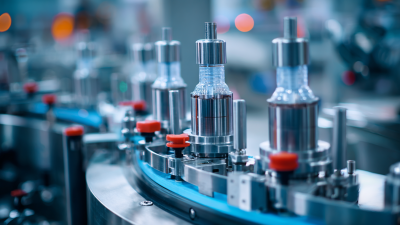

Key Features to Look for in a Lip Gloss Filling Machine

When selecting a lip gloss filling machine, several key features are essential to ensure it meets your production needs efficiently. First, consider the machine's versatility; it should accommodate various tube sizes and types, as the trend toward cosmetic tubes is on the rise due to their specialized dispensing and eco-friendly attributes.

Additionally, look for advanced automation capabilities that enable quick changeovers and minimal downtime, essential for maximizing production output.

Additionally, look for advanced automation capabilities that enable quick changeovers and minimal downtime, essential for maximizing production output.

Another critical feature is precision in filling accuracy. A machine that can deliver consistent fill volumes will not only enhance product quality but also minimize waste, which is increasingly important as the cosmetic industry continues to grow. Safety and ease of operation should also be prioritized, with user-friendly interfaces and robust safety mechanisms to protect operators and maintain seamless production processes. Investing in these features will ensure that the lip gloss filling machine contributes effectively to your overall production strategy.

Evaluating Different Types of Filling Technologies

When selecting a lip gloss filling machine, understanding the different types of filling technologies available is crucial. The most common filling methods include volumetric, gravimetric, and piston filling. Volumetric filling machines dispense a predetermined volume of product into each container, ensuring consistency and minimizing waste. This method is particularly effective for products with a uniform viscosity, making it a popular choice for many lip gloss manufacturers.

Assessing Machine Capacity and Speed for Efficiency

When selecting a lip gloss filling machine, machine capacity and speed are critical factors that directly impact production efficiency. First, assess the production volume of lip gloss you intend to achieve daily. Choosing a machine with a suitable capacity ensures that you can meet your demand without bottlenecking your production process. Machines with higher capacities can fill larger volumes of product per cycle, which is essential for large-scale operations. However, it's also important to consider the scalability of the machine to accommodate future growth in production needs.

Additionally, the speed of the filling machine plays a significant role in maintaining efficiency. A machine that operates at a higher speed will significantly reduce the overall time needed for production runs, allowing for quicker turnaround times. However, it's crucial to balance speed with accuracy—high-speed machines must still maintain precise filling volumes to prevent waste and ensure product quality. Evaluating these factors will help ensure that the lip gloss filling machine aligns with your production goals while maximizing efficiency.

Capacity and Speed Analysis of Lip Gloss Filling Machines

Budgeting: Investing Wisely in Your Filling Equipment

When selecting a lip gloss filling machine, budgeting plays a crucial role in ensuring that you invest intelligently. According to the latest industry reports by Grand View Research, the global lip gloss market is projected to reach $14.2 billion by 2025, which highlights the growing demand for efficient production machinery. Allocating a reasonable budget for filling equipment can help manufacturers meet this demand without compromising on quality or output.

Tips: Consider the total cost of ownership rather than just the initial purchase price. This includes maintenance, spare parts, and operational costs. Investing in a reliable machine can significantly reduce downtime, which is essential for maintaining productivity and meeting consumer demand.

Furthermore, think about scalability. According to a market analysis by Statista, companies that invest in scalable technology see 30% faster growth. Choosing a filling machine that can adapt to your production needs allows for gradual expansion without the need for frequent reinvestments. This strategic approach ensures that your budget aligns with both current and future production requirements.

Related Posts

-

5 Amazing Tips for Choosing the Right Lotion Filling Machine for Your Business

-

What is a Capping Machine for Bottles and How Can It Benefit Your Production Line?

-

7 Essential Tips for Choosing the Perfect Bottle Labeler

-

The Future of Oil Filling Machines in the Evolving Packaging Industry

-

Exploring Innovative Examples of Capping Machine Technologies in Today's Bottling Industry

-

Understanding the Different Types of Capping Machines and Their Industry Applications

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content