Why Choose a Lip Gloss Filling Machine for Your Business?

In the growing beauty industry, the demand for lip gloss is skyrocketing. According to a recent report by Grand View Research, the global lip gloss market is projected to reach USD 2.36 billion by 2025. This surge presents a significant opportunity for businesses, making a lip gloss filling machine an essential investment.

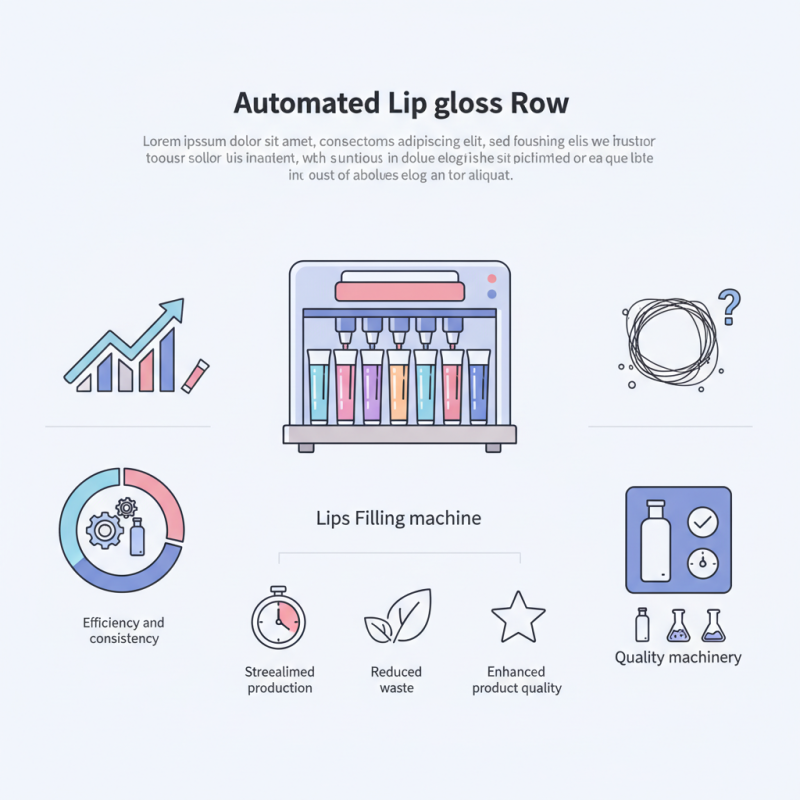

Expert Sarah Thompson, a leading figure in cosmetic manufacturing, emphasizes this point: "Automating the filling process increases efficiency and consistency, vital for any successful beauty brand." Adopting a reliable lip gloss filling machine can streamline production, reduce waste, and enhance product quality. However, not all machines are created equal. Selecting the right equipment requires careful consideration of capacity, ease of use, and compatibility with various formulas.

Despite the clear advantages, many businesses overlook the importance of investing in quality machinery. Some may resort to manual filling methods to save costs, but this often leads to inefficiencies and inconsistencies. A thoughtful approach to selecting a lip gloss filling machine can significantly impact a brand’s success in this competitive landscape.

Benefits of Using a Lip Gloss Filling Machine in Cosmetic Production

Choosing a lip gloss filling machine can greatly enhance cosmetic production. The global lip care market is expected to reach $5.15 billion by 2025, highlighting strong demand. Producing consistent and high-quality products is crucial. A filling machine ensures precise filling, reducing waste and enhancing efficiency.

Manual filling processes often lead to variability in product quality. This inconsistency can deter customers. According to industry reports, automated systems can increase production speed by up to 50%. Furthermore, they minimize operator error, allowing for better quality control. With fewer resources spent on corrections, businesses can focus on growth.

The initial investment may seem high, but the long-term benefits are notable. A machine can fill multiple formats like tubes and pots, catering to various market needs. Adjusting to changing trends is easier. Still, not every machine is a perfect fit. Businesses must evaluate their specific needs and production scale. Finding the right machine may require effort and trial. Each brand has unique requirements that should not be overlooked.

Key Features to Look for in a Lip Gloss Filling Machine

In the competitive beauty industry, a lip gloss filling machine can enhance efficiency and productivity. Key features in these machines play a significant role in decision-making. One crucial aspect is the filling speed. According to industry reports, machines can fill between 30 to 100 containers per minute. This speed can significantly reduce production time, especially for businesses with high demand.

Another important feature is precision. An accurate filling machine minimizes product waste and ensures consistent quality. Inconsistent filling can lead to customer dissatisfaction and revenue loss. Many machines now offer adjustable nozzles for different container sizes. This flexibility allows businesses to adapt to changing trends without major investments.

Ease of cleaning and maintenance is often overlooked. Frequent product changes require machines to be cleaned regularly. A design that allows for quick disassembly and cleaning can save both time and labor costs. However, not every machine offers this convenience. Businesses should evaluate the long-term operational costs and reflect on how an inefficient system may affect growth. Addressing these aspects early can foster sustainability and brand loyalty in a continuously evolving market.

Industry Growth Trends: The Demand for Lip Gloss Packaging Solutions

The lip gloss market has witnessed remarkable growth in recent years. According to a recent market research report, the global lip gloss market is projected to reach USD 4.5 billion by 2026, with a CAGR of 5.6% from 2021 to 2026. This growth is driven by the rising consumer preference for beauty products that offer hydration and shine. The demand for innovative packaging solutions plays a significant role in this trend. Brands are looking for efficient filling machines that ensure consistency and quality in lip gloss packaging.

While many businesses remain focused on product quality, packaging cannot be overlooked. The right lip gloss filling machine increases production efficiency and reduces waste. However, choosing the wrong machine can lead to operational challenges. Downtime and maintenance issues can become costly. Surprisingly, 25% of manufacturers reported inefficiencies in their current packaging lines. A well-designed filling machine should address these issues, providing versatility for different formulas and packaging styles.

Moreover, as sustainability becomes a priority, the industry is responding. Many businesses are exploring eco-friendly packaging options and more sustainable filling processes. Yet, the shift to greener solutions can be complex. Companies need to carefully consider their choices. The demand for effective lip gloss filling machines that align with these trends is essential. Brands must invest in technology that meets both quality and environmental standards.

Cost Efficiency: How Filling Machines Enhance Profit Margins

Investing in a lip gloss filling machine can significantly boost your business's profit margins. These machines streamline the production process, allowing for quicker filling and packaging. By automating the filling, you reduce labor costs and minimize human error, which often leads to waste. Every drop counts, especially in the cosmetic industry, where precision matters.

The initial cost of such machines may seem high. However, over time, businesses notice a marked decrease in operational costs. They can produce more units in less time. This increase in efficiency translates directly into higher sales. Yet, it’s crucial to choose the right machine, as not every model suits every business need. Some may require more maintenance or might not fit your production scale perfectly.

Moreover, quality control can be a challenge with machines. Small variations in filling can impact product quality. Regular calibration and checks are necessary to maintain standards. Reflecting on these aspects is vital before making a decision. In essence, while a filling machine can enhance cost efficiency, careful planning is needed for it to truly benefit your operation.

Quality Control: Ensuring Consistency in Lip Gloss Products

When it comes to lip gloss production, quality control is paramount. Studies show that over 70% of consumers prioritize product consistency. This consistency begins with reliable filling machines. A high-quality lip gloss filling machine minimizes variations in volume and weight, leading to uniformity across products. Such consistency can enhance brand reputation and customer satisfaction.

However, achieving this quality is not without its challenges. Slight inconsistencies can arise from machine calibration or ingredient viscosity. A report by a leading industry analyst highlights that 15% of production runs experience variability due to these factors. Investing in a precision filling machine can mitigate these issues, ensuring that each tube contains the same delightful formula.

Moreover, regular maintenance of filling machines is crucial. Neglecting maintenance can lead to malfunction and contamination. A recent survey indicated that 20% of companies reported losses due to quality issues linked to equipment failure. Ensuring operational efficiency requires diligence and constant evaluation. In an industry where appearance and feel are everything, taking these steps can define a brand's success.

Related Posts

-

5 Amazing Tips for Choosing the Right Lotion Filling Machine for Your Business

-

Why Invest in a Lip Gloss Filling Machine for Your Cosmetic Business?

-

Understanding the Different Types of Capping Machines and Their Industry Applications

-

Maximizing Efficiency: The Future of Oil Filling Machines in High-Volume Production

-

Exploring Trends in Bottle Filling Machines at China’s 138th Canton Fair 2025

-

Ultimate Guide to Choosing the Right Label Applicator Machine for Your Business

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content