How Bottle Labeling Machines Revolutionize Efficiency in Packaging Industries

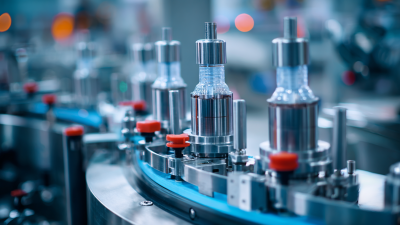

In the fast-paced landscape of the packaging industry, the implementation of advanced machinery has become crucial for enhancing productivity and efficiency. The bottle labeling machine is at the forefront of this transformation, streamlining operations and reducing labor costs significantly.

According to a report by Grand View Research, the global labeling machine market is projected to reach USD 8.98 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.7%. This growth is driven by the rising demand for effective branding and compliance in product packaging. Moreover, the efficiency of bottle labeling machines reduces error rates and minimizes product wastage, crucial factors for companies aiming to optimize their supply chain. As manufacturers adopt automation technologies, the role of bottle labeling machines is expected to become increasingly pivotal, ultimately redefining standards in packaging efficiency and accuracy.

Understanding the Role of Bottle Labeling Machines in Modern Packaging

In today's fast-paced packaging industries, bottle labeling machines have become indispensable for achieving greater efficiency. According to a market research report by Smithers Pira, the global labeling machinery market is projected to reach $4.5 billion by 2025, indicating a robust growth fueled by technological advancements. These machines not only enhance speed but also improve precision, allowing companies to maintain high standards of quality while meeting increasing consumer demand.

Bottle labeling machines streamline the packaging process by automating the application of labels, which reduces labor costs and minimizes errors. The benefits extend beyond just speed; manufacturers can achieve label application rates exceeding 300 bottles per minute. With an estimated 25% increase in productivity attributed to the automation of labeling processes, businesses can significantly improve their output and profitability.

Bottle labeling machines streamline the packaging process by automating the application of labels, which reduces labor costs and minimizes errors. The benefits extend beyond just speed; manufacturers can achieve label application rates exceeding 300 bottles per minute. With an estimated 25% increase in productivity attributed to the automation of labeling processes, businesses can significantly improve their output and profitability.

Tip: When selecting a bottle labeling machine, consider models that offer flexibility for different bottle sizes and label formats, as this can further enhance production efficiency.

Moreover, integrating smart technology such as IoT capabilities can provide real-time data analytics, allowing for quicker adjustments and improved maintenance of the labeling process.

Tip: Regular maintenance checks can prevent downtime and ensure the machines operate at peak efficiency, ultimately saving costs in the long run.

Key Features and Technologies of Advanced Labeling Machines

Advanced bottle labeling machines are transforming efficiency in packaging industries through their innovative features and technologies. One key aspect is automation, which significantly reduces labor costs and human error. These machines can automatically apply labels at high speeds, allowing for increased throughput without compromising on accuracy. This not only accelerates the packaging process but also ensures that each bottle is uniformly labeled, enhancing the overall presentation and quality of the product.

Another important feature is the adaptability of advanced labeling machines. Many of these systems support various label types, sizes, and materials, making them versatile for different products. Equipped with smart sensors and vision systems, these machines can detect misalignment or label errors in real-time, minimizing waste and downtime. The integration of IoT (Internet of Things) technology also allows for remote monitoring and maintenance, enabling producers to optimize their operations and respond quickly to any issues that arise during the labeling process. This technological advancement is crucial in meeting the growing demands of the packaging industry.

Efficiency of Advanced Bottle Labeling Machines by Technology Type

Step-by-Step Guide to Implementing Bottle Labeling Machines in Production

Implementing bottle labeling machines in production can significantly enhance efficiency and accuracy in packaging operations. According to a recent report by Grand View Research, the global labeling machine market is expected to reach $5.26 billion by 2025, growing at a CAGR of 5.2%. This growth can largely be attributed to the increasing demand for automation in manufacturing processes, as companies seek to reduce labor costs and improve productivity. To successfully integrate these machines, it's essential to conduct a step-by-step evaluation.

First, businesses should assess their labeling needs and production capacity. Understanding the volume of products and types of labels required helps in selecting the right machine. For instance, high-speed labeling machines can process over 300 bottles per minute, making them ideal for large-scale production. Following this, procurement and installation should be streamlined. Working closely with equipment vendors during this phase can ensure optimal setup and minimize downtime. Finally, consistent employee training on the operation and maintenance of these machines will ensure longevity and efficiency, leading to a more productive packaging line. By investing in bottle labeling technology, companies can achieve remarkable improvements in their operational efficiency and output quality.

Troubleshooting Common Issues with Bottle Labeling Machines

Bottle labeling machines have become essential tools in the packaging industry, significantly enhancing operational efficiency. However, like any machinery, they can occasionally encounter issues that disrupt production. Common problems include label misalignment, adhesive failure, and machine jams. Addressing these issues promptly is crucial to maintain a smooth workflow and avoid costly downtime.

One of the primary concerns is label misalignment. This often occurs due to improper setup or mechanical wear over time. Regularly inspecting and calibrating the machine can help ensure accurate label placement. Additionally, using high-quality labels and adhesives specifically designed for the machine can mitigate the risk of adhesion failures, preventing labels from peeling or falling off during transit.

Machine jams can also halt production, often caused by debris buildup or worn-out components. Keeping the machine clean and performing routine maintenance checks can prevent these jams. Operators should be trained to troubleshoot basic issues, allowing for quick resolutions and less disruption to the packaging process. By proactively addressing these common problems, companies can maximize the efficiency and reliability of their bottle labeling operations.

Measuring and Analyzing Efficiency Gains from Labeling Automation

The introduction of bottle labeling machines has greatly transformed the efficiency of packaging industries by automating processes that were previously manual. According to a report by Smithers Pira, the global labeling market is expected to reach $50 billion by 2025, highlighting the growing demand for labeling automation. By integrating advanced technologies, such as machine vision and robotic handling, these machines minimize human error and increase throughput. This ensures that products are labeled quickly and accurately, which is critical for maintaining compliance and enhancing brand integrity.

In terms of quantifiable efficiency gains, a study conducted by Packaging Strategies revealed that companies implementing labeling automation can achieve a productivity increase of up to 30%. This is particularly significant in high-volume production environments where speed and accuracy are paramount. Furthermore, efficiency in labeling can lead to reduced wastage and lower operational costs, thereby improving overall profitability. As automated labeling systems continue to evolve, their ability to seamlessly integrate into existing production lines will further drive efficiency gains, making them essential tools for any forward-thinking packaging operation.

How Bottle Labeling Machines Revolutionize Efficiency in Packaging Industries - Measuring and Analyzing Efficiency Gains from Labeling Automation

| Efficiency Metric | Before Automation | After Automation | Percentage Improvement (%) |

|---|---|---|---|

| Labeling Speed (Labels/Minute) | 30 | 75 | 150% |

| Labor Cost per Bottle ($) | 0.15 | 0.05 | 66.67% |

| Label Application Accuracy (%) | 90 | 99 | 10% |

| Downtime (Hours/Week) | 10 | 2 | 80% |

| Waste Material (Labels/Batch) | 50 | 10 | 80% |

Related Posts

-

Understanding the Different Types of Capping Machines and Their Industry Applications

-

How to Choose the Right Bottle Labeler for Your Business Needs

-

Maximizing Efficiency with Automatic Label Applicator Benefits for Global Buyers

-

Ultimate Guide to Choosing the Right Label Applicator Machine for Your Business

-

How to Choose the Right Automatic Liquid Filling Machine for Your Business Needs

-

How to Choose the Perfect Lip Gloss Filling Machine for Your Production Needs

30 Beach Street, Mt Vernon, NY 10550

914-239-3878 sale@bbqmachine.com

© 2025 by TurboFil Packaging Machines, LLC

© 2025 by TurboFil Packaging Machines, LLC

Skip to content

Skip to content